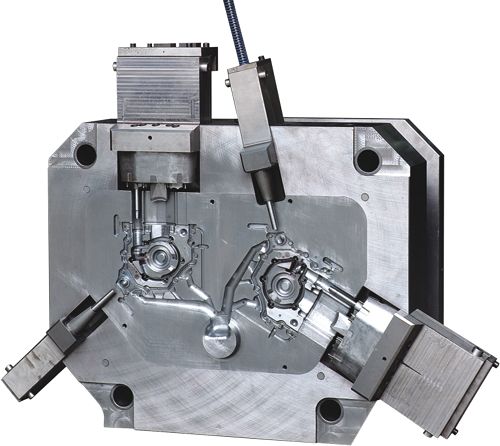

Die casting mold has advantages as below:

1. Die cast mold can cast metal parts with features of complex structure, clear outline, thin wall and deep cavity

2. Die cast mold can manufacture casting parts with high accuracy

3. Die cast mold make full use of the aluminum alloy or zinc alloy material with little waste

4. Automatic production by die casting mold and machines greatly shorten lead time even with big quantity order

Die casting mold has disadvantages as below:

1. Aluminum or zinc die casting parts will have air pores ,so they are not suitable for heat treatment.

2. Die cast mold cost is a little expensive due to its material cost and design labor cost, so die casting process is more suitable for big quantity production

3. Die cast mold is designed for not big size parts.

4. Die casting materials are not various, regularly is aluminum alloy and zinc alloy.